Product details

ORDER CODES:

|

EDG - |

G01 - |

H2 - |

D1 - |

R |

|

Model

Name |

Thread

Connection |

Pressure

Adjusting Range |

Coil

Resistance |

Safety

Valve |

|

EDG |

G01

: 1/4" |

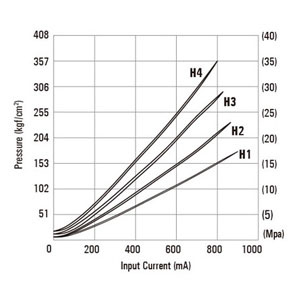

H1

: 10~143 kgf/cm2 ( 1.0~14 Mpa ) H2

: 15.3~214 kgf/cm2 ( 1.5~21 Mpa ) H3

: 15.3~286 kgf/cm2 ( 1.5~28 Mpa ) H4

: 20~357 kgf/cm2 ( 2.0~35 Mpa ) |

D1

: 10Ω D2

: 20Ω |

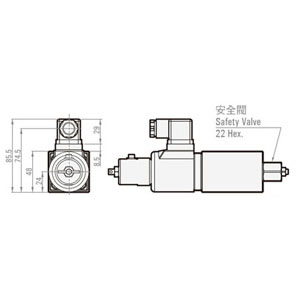

R

: with safety valve none

: without safety valve |

SPECIFICATION:

|

Model |

EDG-G01 |

|

Max.

Flows |

1.2

l/min |

|

Pressure

Adjusting Range |

H1

: 10~143 kgf/cm2 ( 1.0~14MPa ) H2

: 15.3~214 kgf/cm2 ( 1.5~21MPa ) H3

: 15.3~286 kgf/cm2 ( 1.5~28MPa ) H4

: 20~357 kgf/cm2 ( 2.0~35MPa ) |

|

Rated

Current |

800

mA |

|

Coil

Resistance |

10Ω

or 20Ω ( 20°C ) |

|

Magnetic

Hysteresis |

<3% |

|

Repeatability |

<1% |

|

Amplifier

No. |

TW2085 |

|

Weight |

1.6

kg |

* Note: Value when a

WILSON amplifier TW2085 is used (with dithering).

BUNDLED ACCESSORIES:

|

Model |

Mounting Bolts |

Q'ty |

|

EDG-G01 |

M5

x L45 |

4 |

HANDLING:

1. Air Bleeding : To enable proper

pressure control, loosen the air vent when starting up the pump in order to

drain any air from the pump, and fill the insideof the solenoid with hydraulic

operational fluid. The position of the air vent can change by loosening the M4

screw and rotating the cover.

2. Mounting Method : Mounting on a

vertical surface causes minimum pressure to increase by 2 kgf/cm2

(0.2 Mpa).

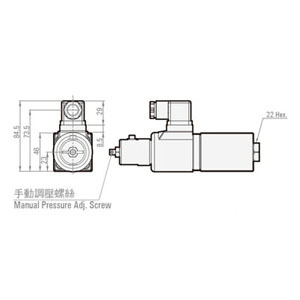

3. Manual Pressure Adjusting Screw : For

the initial adjustment or when there is no input current to the valve due to an

electrical problem or some other reason, valve pressure can be increased by

rotating the manual adjustment screw clockwise (rightward). Normally, the

manual adjusting screw should be rotated back fully to the left

(counterclockwise) and secured with the lock nut.

4. Please minimize the oil pressure in

the return line, and make sure that the output of independent tube must be

under the oil surface in the tank.

5. Minimum Relief Flow Rate : A small

flow rate can cause setting pressure to become unstable. Use a flow rate of at

least 0.3 l/min.

6. Load Capacity : When using this valve

to control direct circuit pressure, make sure the load volume (P port side

volume) is at least 40 cm3.

7. Use an operating fluid that conforms

to the both of the following.

Oil temperature: -20 to 70°C.

Viscosity: 12 to 400mm2/s.

The recommended viscosity range is 15 to 60mm2/s.