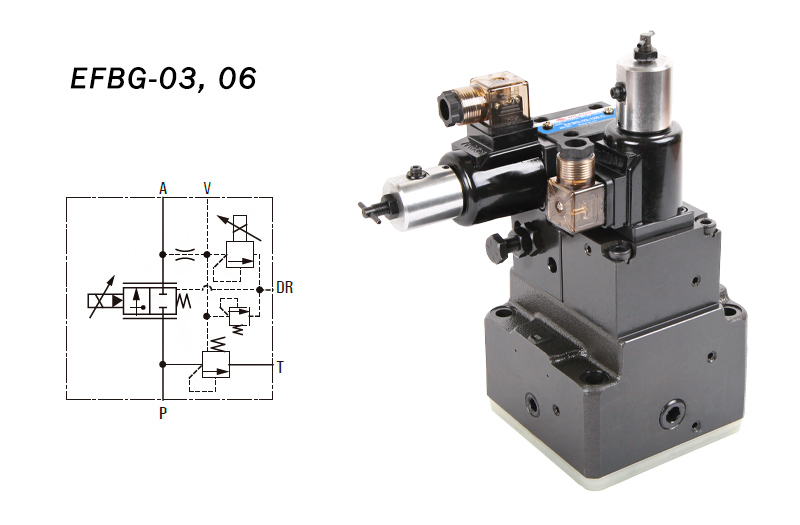

Product details

ORDER CODES:

|

EFBG - |

03 - |

125 - |

C - |

R2 |

|

Model

Name |

Thread

Connection |

Max.

Flow |

Max.

Operational Pressure |

Pressure

Control Range |

|

EFBG |

03

: 3/8" 06

: 3/4" |

60/125

l/min 250

l/min |

C

: 140 kgf/cm2 H

: 255 kgf/cm2 |

R1

: 12.2~71 kgf/cm2 (1.2~7Mpa) R2 : 14.3~143 kgf/cm2 (1.4~14Mpa) R3 : 16.3~214 kgf/cm2

(1.6~21Mpa) R4 : 16.3~255 kgf/cm2

(1.6~25Mpa) |

SPECIFICATION:

|

Model |

EFBG-03 |

EFBG-06 |

|

|

Max.

Operational Pressure |

255

kgf/cm2 ( 25 MPa ) |

||

|

Max.

Flows |

60/125

l/min |

250

l/min |

|

|

Flowing

System |

Flow

Adjusting Range |

1

~ 60 l/min 1

~ 125 l/min |

5

~ 250 l/min |

|

Internal

Resistance of This Valve |

5.1

kgf/cm2 ( 0.5 MPa ) <note1> |

7.1

kgf/cm2 ( 0.7 MPa ) <note1> |

|

|

Rated

Current |

800

mA |

||

|

Coil

Resistance |

20Ω

( 20°C ) |

||

|

Magnetic

Hysteresis |

<3%

<note2> |

||

|

Repeatability |

<1% |

||

|

Pressure

System |

Pressure

Control Range |

R1

: 12.2~71 kgf/cm2 (1.2~7 MPa) R2

: 14.3~143 kgf/cm2 (1.4~14MPa) R3

: 16.3~214 kgf/cm2 (1.6~21MPa) R4

: 16.3~255 kgf/cm2 (1.6~25MPa) |

|

|

Max.

Operational Pressure |

C

: 140 kgf/cm2 H

: 255 kgf/cm2 |

||

|

Rated

Current |

C

: 700 mA H

: 800 mA |

||

|

Coil

Resistance |

20Ω

( 20°C ) |

||

|

Magnetic

Hysteresis |

<3% |

||

|

Repeatability |

<1% |

||

|

Amplifier

No. |

TW9820

series |

||

|

Weight |

14

kg |

28

kg |

|

* Note:

1. Indicates the pressure differential between the valve P port and A

port.The left chart is complied with our standard electronic control circuit

board TW9820-2, and is the single valve test result.

2. Value when a WILSON amplifier TW9820-2 is used (with dithering).

3. These specifications apply to valves that include an

electro-hydraulic proportional pilot relief valve.

4. The maximum adjustment pressure is 255kgf/cm2 (25MPa max.)

for a valve that does not include an electro-hydraulic proportional pilot

relief valve. Factory default is minimum output 35.7kgf/cm2 (3.5MPa

max.) Set this value in accordance with the pressure of the hydraulic circuit

being used.

BUNDLED ACCESSORIES:

|

Model |

Mounting Bolts |

Q'ty |

|

EFBG-03 |

M10

x L75 |

2 |

|

M10

x L90 |

2 |

|

|

EFBG-06 |

M16

x L100 |

2 |

|

M16

x L135 |

2 |

HANDLING:

1. Air Bleeding : In order to ensure

stable control, loosen the air vent and bleed air from the valve before

starting operation.

2. Manual Adjusting Screw : For the

initial adjustment or when there is no input current to the valve due to an

electrical problem or some other reason, pressure or flow rate can be increased

by rotating the manual adjustment screw clockwise (rightward). Normally, this

adjusting screw should be returned completely to its original position and

secured with the lock nut.

3. Please minimize the oil pressure in

the return line, and make sure that the output of independent tube must be

under the oil surface in the tank.

4. Safety Valve Setting Pressure : For a

safety valve without an electro hydraulic proportional pilot relief valve,

safety valve pressure is set to minimum pressure 35.7kgf/cm2 (3.5Mpa

max.) In the case of a safety valve with an electrohydraulic proportional pilot

relief valve, the safety valve setting pressure is set to the minimum

adjustment pressure plus 15.3kgf/cm2 (1.5Mpa). When actually using

the valve, adjust in accordance with hydraulic circuit pressure.

5. Minimum Relief Flow Rate During

Pressure Control : Setting pressure can become unstable when the relief flow

rate to the valve's T port is small. Because of this, use a relief flow rate of

at least 10 l/min with a nominal diameter of 03 or 06.

6. Valve Mounting Orientation : When an

electro-hydraulic proportional pilot relief valve main valve is mounted on a

vertical surface with the pilot relief valve part facing downwards make it

difficult to bleed air from the pilot relief valve. Because of this, you should

not use this type of mounting orientation.

7. Use an operating fluid that conforms

to the both of the following.

Oil temperature: -20 to 70°C.

Viscosity: 12 to 400mm2/s.

The recommended viscosity range is 15 to 60mm2/s.