Product details

ORDER CODES:

|

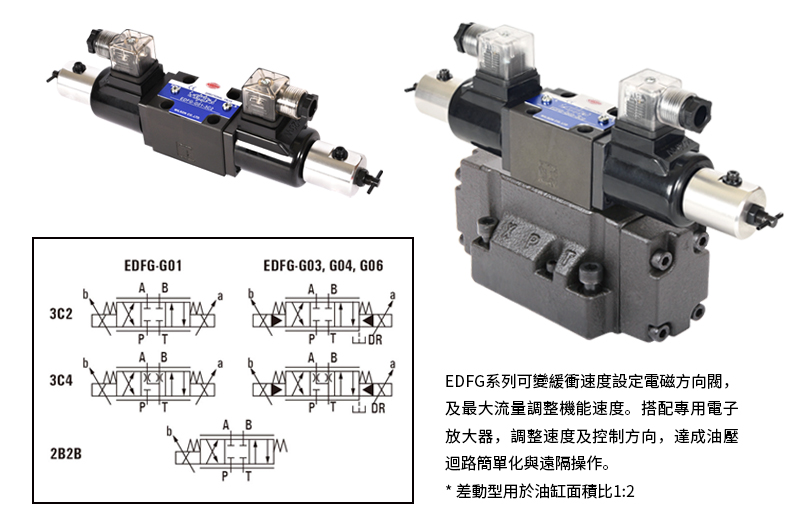

EDFG - |

G03 - |

3C2 - |

XY |

|

Model

Name |

Thread

Connection |

Spool

Type |

Drain

Type |

|

EDFG |

G01

: 1/4" G03

: 3/8" G04

: 1/2" G06

: 3/4" G10

: 1-1/4" |

3C2 3C4 2B2B |

XY

: external pilot and external drain *

EDFG-G01 is not applicable |

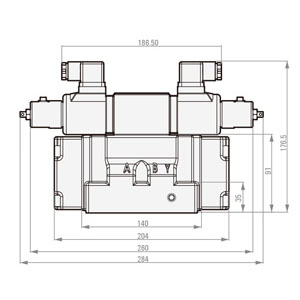

SPECIFICATION:

|

Model |

EDFG-G01 |

EDFG-G03 |

EDFG-G04 |

EDFG-G06 |

|

Max.

Operational Pressure |

225 kgf/cm2 ( 25 MPa ) |

|||

|

Rated

Flow |

10/25

l/min |

40/80

l/min |

140

l/min |

250

l/min |

|

Pilot

Pressure |

- |

>10

kgf/cm2 (1.0 MPa) |

>10

kgf/cm2 (1.0 MPa) |

>10

kgf/cm2 (1.0 MPa) |

|

Pilot

Flow |

- |

>2

l/min |

>3

l/min |

>5

l/min |

|

Allowable

Back Pressure of T port |

25.5

kgf/cm2 ( 2.5 MPa ) |

25.5

kgf/cm2 (2.5 MPa) |

||

|

Rated

Current |

850 mA |

|||

|

Coil

Resistance |

20Ω ( 20°C ) |

|||

|

Magnetic

Hysteresis |

<5% |

|||

|

Repeatability |

0.04

sec |

0.05

sec |

0.08

sec |

0.1

sec |

|

Amplifier

No. |

TW9820 series |

|||

|

Weight |

2.2

kg |

6.6

kg |

7.8

kg |

12.9

kg |

* Note:

1. Value when

pressure drop volume to P→A and P→B

is ΔP = 10 kgf/cm2 (1.0 MPa).

2. Indicates maximum

throughput volume value between each port.

3. Indicates

differential between the pilot port and tank port, or drain port.

4. Value when 0.1

second is assumed for the response time from zero to the rated flow volume.

5. Value when a

WILSON amplifier TW9820-2 is used.

6. Response time is

typical value for a supply pressure of 143 kgf/cm2 (14 MPa) and

fluid temperature of 40°C (kinematic viscosity: 40 mm2/s).

BUNDLED ACCESSORIES:

|

Model |

Mounting Bolts |

Q'ty |

|

EDFG-G01 |

M5

x L45 |

4 |

|

EDFG-G03 |

M6

x L35 |

4 |

|

EDFG-G04 |

M6

x L45 |

2 |

|

M10

x L50 |

4 |

|

|

EDFG-G06 |

M120

x L60 |

6 |

HANDLING:

1.

Air Bleeding : In order to ensure stable control, loosen the air vent and bleed

air from the valve before starting operation.

2.

T Port Piping : When configuring piping, ensure that the T port (pilot valve T port

for the G03, G04, and G06 sizes) is filled with operational fluid.

3.

Manual Adjusting Screw : For the initial adjustment or when there is no input current

to the valve due to an electrical problem or some other reason, the valve can

be operated and valve pressure can be increased by rotating the manual adjustment

screw clockwise (rightward). Normally, the manual adjusting screw should be

rotated back fully to the left (counterclockwise).

4.

Valve Mounting Orientation : Install the valve so the spool axis line is

horizontal.

5.

Combining with a Pressure Compensation Valve : Use of the optional pressure compensation

kit is recommended when higher precision flow rate control is required or in

high-pressure applications.

6.

If pilot pressure exceeds 92 kgf/cm2 (9 MPa) use a modular type P

port reduction valve (MBRV-02-P-1) at a setting of 20 kgf/cm2 (2

MPa) (only for EDFG-G03, G04, G06).

7.

On a system that requires large brake pressure during deceleration or a system that

uses a vertical cylinder, equip a counter balance valve. Use a single rod, if the

rod exit is not slowed sufficiently, use a counter balance valve on the rod.

8.

Maintain hydraulic operational fluid contamination so it is at least Class 9.

9.

Use an operating fluid that conforms to the both of the following.

Oil temperature: -20 to 70°C.

Viscosity:

12 to 400mm2/s.

The recommended viscosity range is 15 to

60mm2/s.